Spectralock 1 Instructions: A Comprehensive Guide

This guide details the application of SPECTRALOCK 1, a professional-grade, pre-mixed grout from LATICRETE. It covers installation, safety, and resources, referencing Data Sheet 36589.5 for detailed instructions.

Optimize Facebook Login and cross-play to improve the Facebook Login Rate in your native game app. Gaming Login unlocks features and services, aiding acquisition and engagement.

LATICRETE representatives review SPECTRALOCK 1 (SL1), providing insights into its application and benefits, as outlined in model 3191-0001-2 instructions.

SPECTRALOCK 1 represents a significant advancement in grout technology, offering a pre-mixed, high-performance solution for tile installations. This innovative product, developed by LATICRETE, simplifies the grouting process while delivering exceptional durability and aesthetic appeal. Understanding its unique properties and proper application techniques is crucial for achieving long-lasting, beautiful results.

This introduction serves as a foundational overview, preparing installers for a detailed exploration of the installation process. Referencing Data Sheet 36589.5, “How To Install SPECTRALOCK 1 Pre-Mixed Grout,” is highly recommended. Furthermore, resources like online tutorials and support from LATICRETE representatives are available to ensure a successful application.

SPECTRALOCK 1 is designed for both residential and commercial projects, offering a reliable and consistent finish. Its ease of use and superior performance make it a preferred choice among tiling professionals.

What is Spectralock 1?

SPECTRALOCK 1 is a professional-grade, epoxy-based grout formulated by LATICRETE, specifically designed for superior performance and ease of use. Unlike traditional cementitious grouts, SPECTRALOCK 1 arrives pre-mixed, eliminating on-site mixing and ensuring consistent quality. It’s identified by model number 3191-0001-2 and is available in various colors, including 91 Slate Grey.

This grout excels in demanding applications, offering exceptional stain resistance, chemical resistance, and durability. It’s ideal for installations requiring a waterproof and hygienic surface. Detailed installation guidance is found in Data Sheet 36589.5, outlining the proper techniques for optimal results.

SPECTRALOCK 1 streamlines the grouting process, reducing labor time and minimizing waste, making it a cost-effective solution for professional tilers.

Key Features and Benefits

SPECTRALOCK 1 boasts exceptional stain resistance, crucial for high-traffic areas and demanding environments. Its pre-mixed formula ensures consistent color and simplifies installation, eliminating mixing errors. The epoxy base delivers superior chemical resistance, protecting against harsh cleaning agents and spills.

Durability is a key benefit, minimizing cracking and failure, as detailed in troubleshooting resources. It’s suitable for various tile types and joint widths, offering versatility. Furthermore, SPECTRALOCK 1 contributes to a hygienic surface due to its non-porous nature.

Reduced labor time and waste contribute to cost savings, making it an efficient choice. Refer to Data Sheet 36589.5 for comprehensive application instructions and optimal performance.

Preparation Before Application

Proper surface preparation is vital for SPECTRALOCK 1’s performance. Ensure substrates meet requirements, and gather necessary tools and materials before beginning installation, per instructions.

Surface Preparation

Thorough surface preparation is absolutely critical before applying SPECTRALOCK 1 pre-mixed grout. All substrates must be clean, structurally sound, and free from dust, debris, oil, grease, curing compounds, paint, or any other contaminants that could hinder adhesion.

Verify that the substrate is properly leveled and adequately rigid to support the tile installation and the weight of the grout. Any loose or damaged substrate components should be repaired or replaced prior to grout application.

Refer to Data Sheet 36589.5 for specific substrate preparation recommendations, as requirements can vary depending on the type of substrate being used. Proper preparation ensures optimal grout performance and longevity, preventing issues like cracking or failure.

Substrate Requirements

SPECTRALOCK 1 is compatible with a wide range of substrates, but specific requirements must be met for optimal performance. Acceptable substrates include well-cured concrete, cement mortar beds, and exterior-grade plywood. However, substrates must be structurally sound, stable, and free of movement.

Ensure the substrate is properly leveled and free from cracks or voids. Substrates with excessive deflection may require reinforcement.

Always consult Data Sheet 36589.5 for detailed substrate compatibility information. Unacceptable substrates include gypsum board, particleboard, and any surface with inadequate bonding properties. Proper substrate selection is crucial for a durable and long-lasting tile installation with SPECTRALOCK 1.

Tools and Materials Needed

For a successful SPECTRALOCK 1 installation, gather essential tools and materials beforehand. You’ll require a grout float, typically made of rubber, for efficient application. Sponges – both large and small – are vital for cleaning excess grout. Buckets are needed for mixing (though SPECTRALOCK 1 is pre-mixed, water may be added for consistency) and rinsing.

Protective gloves and eye protection are crucial safety items. A grout saw or utility knife helps with removing grout from tile surfaces;

Refer to Data Sheet 36589.5 for a comprehensive list. Ensure adequate ventilation and have appropriate cleaning solutions readily available for haze removal and final polishing.

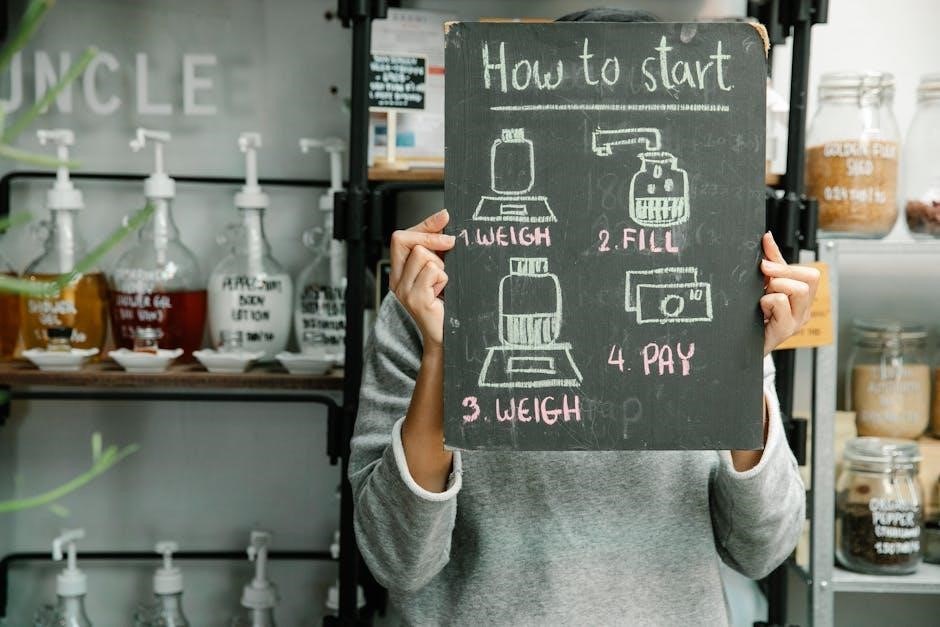

Installation Process: Step-by-Step

Follow Data Sheet 36589.5 for detailed SPECTRALOCK 1 installation. Apply the pre-mixed grout, working it into joints, then clean excess material with sponges and water.

Mixing Spectralock 1 (Premixed)

SPECTRALOCK 1 is supplied pre-mixed, eliminating on-site mixing and ensuring consistent color and performance. However, thorough stirring is crucial before application to homogenize the product and achieve optimal workability. Use a low-speed mixer – avoid high speeds that can introduce excessive air.

Stir for a minimum of 3-5 minutes, scraping the sides and bottom of the container to incorporate any settled solids. Ensure a smooth, creamy consistency is achieved. Do not add any water or other additives, as this will compromise the grout’s properties and potentially void the warranty. Inspect the grout for any lumps or inconsistencies; continue mixing until a uniform texture is obtained.

Proper mixing is essential for successful installation, contributing to consistent color, ease of application, and long-term durability. Refer to Data Sheet 36589.5 for further guidance.

Applying the Grout

Begin applying SPECTRALOCK 1 using a grout float, holding it at a 45-degree angle to the tile surface. Work in a diagonal direction, forcing the grout into the joints, ensuring complete fill. Avoid applying excessive pressure, which can smear the grout onto the tile face. Regularly remove excess grout from the surface with the float, maintaining a clean working area.

For narrow joints, a smaller grout float may be preferable. Ensure consistent coverage and full joint filling. After initial application, allow a brief setting time (refer to working time guidelines) before proceeding to the next step. Proper application is vital for a waterproof and aesthetically pleasing result.

Consult Data Sheet 36589.5 for detailed application techniques and best practices to achieve optimal performance with SPECTRALOCK 1.

Working Time and Open Time

SPECTRALOCK 1 offers a unique working time, crucial for efficient installation. “Working time” refers to the period you have to apply the grout after mixing – typically around 45-60 minutes, but this can vary with temperature and humidity. “Open time” describes how long you can leave the grout in the joints before cleaning begins, generally 15-30 minutes.

These times are approximate and should be verified based on environmental conditions. Higher temperatures accelerate setting, shortening both working and open times. Conversely, cooler temperatures extend these periods. Always refer to Data Sheet 36589.5 for precise timings and adjustments.

Efficient workflow is key to maximizing usability. Prepare only the amount of grout you can apply within the working time to avoid waste and ensure optimal performance.

Grout Application Techniques

Applying SPECTRALOCK 1 requires specific techniques for optimal results. Use a rubber grout float, holding it at a 45-degree angle to the tile surface. Work diagonally across the joints, ensuring complete filling without leaving voids. Avoid excessive pressure, which can pull grout out of the joints.

Remove excess grout promptly with the float, moving diagonally again to clean the tile surface. This prevents haze formation. Follow up with a damp sponge, rinsing frequently in clean water. Multiple passes may be needed to achieve a smooth, even finish.

Refer to Data Sheet 36589.5 for detailed visual guidance. Proper technique minimizes cleanup and maximizes the aesthetic appeal of your tiled surface.

Specific Application Considerations

SPECTRALOCK 1 suits various tile types and joint widths. Data Sheet 36589.5 details recommendations for vertical surfaces and large format tile installations, ensuring optimal performance.

Tile Types Suitable for Spectralock 1

SPECTRALOCK 1 demonstrates exceptional versatility, accommodating a broad spectrum of tile materials. Porcelain, ceramic, glass, and natural stone tiles are all excellent candidates for application with this advanced grout. However, meticulous attention to substrate preparation remains paramount, regardless of the tile type selected.

Specifically, the product excels with dense, non-porous tiles, providing superior stain resistance and durability. While suitable for many natural stones, testing in an inconspicuous area is always recommended to verify compatibility and prevent potential discoloration.

Furthermore, LATICRETE’s resources, including Data Sheet 36589.5, offer detailed guidance on specific tile characteristics and potential considerations for optimal SPECTRALOCK 1 performance. Always consult these resources for the most up-to-date recommendations.

Joint Width Recommendations

SPECTRALOCK 1 performs optimally within specific joint width parameters. Generally, a joint width between 1/16” (1.6mm) and 1/2” (13mm) is recommended to ensure proper grout coverage and minimize the risk of cracking or failure. Narrower joints may require increased precision during application, while wider joints might necessitate additional support.

Maintaining consistent joint width is crucial for aesthetic uniformity and structural integrity. Deviations can lead to uneven grout lines and potential water penetration. Referencing Data Sheet 36589.5 provides detailed guidance on achieving optimal joint dimensions.

LATICRETE representatives emphasize the importance of adhering to these recommendations for maximizing the longevity and performance of SPECTRALOCK 1 installations.

Vertical Surface Application

Applying SPECTRALOCK 1 on vertical surfaces requires specific techniques to prevent sagging or slumping. Work in smaller sections, applying the grout from the bottom up, ensuring adequate support during the initial set. Utilize a firm-density grout float and apply consistent pressure to force the grout fully into the joints.

Consider using a slightly stiffer mix consistency for vertical applications, although avoid adding excessive amounts of water, as this can compromise the grout’s strength and durability. Refer to Data Sheet 36589.5 for guidance on adjusting the mix.

LATICRETE representatives suggest frequent tooling and cleaning of the grout lines to maintain a neat and professional appearance on vertical installations.

Large Format Tile Installation

When utilizing SPECTRALOCK 1 with large format tiles, meticulous surface preparation is crucial. Ensure the substrate is exceptionally flat and stable to prevent lippage and uneven grout joints. Wider grout joints may be necessary to accommodate slight variations in tile size, but adhere to recommended joint width guidelines.

Apply the grout in manageable sections, focusing on filling the joints completely. The pre-mixed nature of SPECTRALOCK 1 simplifies this process, but consistent pressure with a grout float is still essential.

Refer to Data Sheet 36589.5 for specific recommendations regarding large format tile installations, and consult with a LATICRETE representative for tailored advice.

Cleaning and Maintenance

SPECTRALOCK 1 requires initial cleaning after grouting, followed by routine procedures. Stain removal techniques are available to maintain its appearance, ensuring long-lasting beauty.

Initial Cleaning After Grouting

The initial cleaning of SPECTRALOCK 1 grout is a crucial step in achieving a flawless finish. After the grout has sufficiently set – typically within 15-30 minutes, but always refer to Data Sheet 36589.5 for precise timing – begin by removing any excess grout from the tile surface using a clean, damp sponge.

Avoid using abrasive cleaners or scouring pads during this initial cleaning phase, as they can damage the grout or tile. Rinse the sponge frequently in clean water to prevent re-depositing grout haze. Multiple passes with a clean, damp sponge may be necessary to completely remove the residue.

Pay close attention to polished surfaces, as they are more susceptible to scratching. A final wipe-down with a clean, dry cloth will help to reveal the true color and enhance the overall appearance of the installation.

Routine Cleaning Procedures

Maintaining the beauty of SPECTRALOCK 1 grout is simple with regular cleaning. For daily or weekly upkeep, use a pH-neutral cleaner specifically designed for tile and grout. Avoid harsh chemicals, abrasive cleaners, and scouring pads, as these can dull the finish and potentially damage the grout over time.

Dilute the cleaner according to the manufacturer’s instructions and apply with a soft cloth or mop. Rinse thoroughly with clean water and allow the surface to air dry. Regular cleaning prevents the buildup of dirt, grime, and stains, preserving the grout’s color and integrity.

For best results, address spills and messes promptly to prevent them from penetrating the grout. Consistent routine cleaning will ensure a long-lasting, beautiful tile installation.

Stain Removal Techniques

Despite SPECTRALOCK 1’s stain resistance, occasional stubborn stains may occur. Identify the stain type to select the appropriate removal method. For oil-based stains, apply a poultice of baking soda and water, let it dry, then gently brush away. Acidic stains like juice or vinegar can be neutralized with a baking soda paste.

For more challenging stains, consider a commercially available grout stain remover, always testing in an inconspicuous area first. Follow the product’s instructions carefully, ensuring adequate ventilation. Avoid abrasive cleaners, which can damage the grout’s surface.

Rinse thoroughly with clean water after stain removal and allow the area to dry completely. Prompt attention to stains will maximize the effectiveness of the cleaning process and maintain the grout’s appearance.

Troubleshooting Common Issues

Address haze with a grout haze remover, color variations with acceptance, and cracking/failure by reviewing installation per Data Sheet 36589.5.

Grout Haze Removal

Grout haze, a common occurrence after Spectralock 1 application, is typically a residue left on the tile surface. This is easily addressed with a dedicated grout haze remover, specifically formulated to dissolve the remaining grout film without damaging the tile or grout itself.

Follow the haze remover manufacturer’s instructions carefully, ensuring proper dilution and application techniques. Generally, the remover is applied to the affected area, allowed to dwell for a specified time, and then thoroughly rinsed with clean water. Multiple applications may be necessary for stubborn haze.

Always test the haze remover in an inconspicuous area first to verify compatibility with your tile. Preventative measures, like using minimal water during grout application and promptly cleaning excess grout, can minimize haze formation. Refer to Data Sheet 36589.5 for further guidance.

Color Variation Concerns

Spectralock 1, like many grouts, can exhibit slight color variations, even within the same batch. This is due to the inherent nature of the pigments used and is considered normal. Factors like substrate absorption, application technique, and cleaning methods can also influence the final grout color.

To minimize noticeable variations, ensure consistent grout application and thorough cleaning; Pre-mixing the entire container of Spectralock 1 before use helps to homogenize the color. It’s advisable to test a small area first to assess the final color appearance.

Acceptable color variation is outlined in LATICRETE’s quality standards. If significant discrepancies are observed, consult with a LATICRETE representative for guidance and potential solutions, referencing Data Sheet 36589.5.

Grout Cracking and Failure

Grout cracking or failure with Spectralock 1 typically stems from inadequate substrate support, excessive movement, or improper installation. Ensure the tile substrate is structurally sound and free from deflection before application. Expansion joints should be correctly placed to accommodate tile and substrate movement.

Insufficient grout coverage or improper mixing can also contribute to issues. Always follow the recommended joint width guidelines and ensure complete grout consolidation during application. Refer to Data Sheet 36589.5 for detailed installation instructions.

If cracking occurs, assess the underlying cause and address it before repair. Contact a LATICRETE representative for guidance on appropriate repair procedures and material selection.

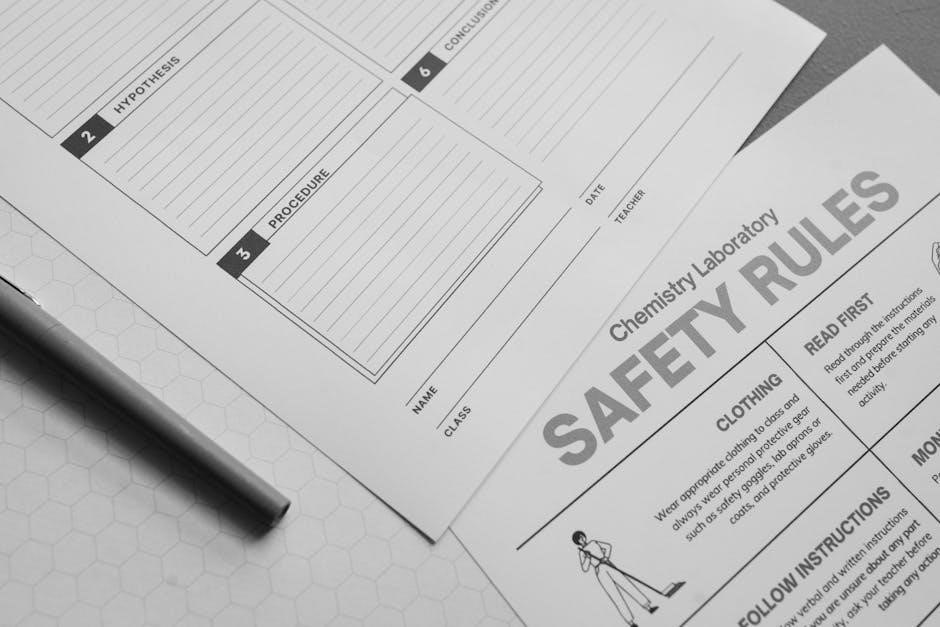

Safety Precautions

Always wear appropriate Personal Protective Equipment (PPE) – gloves, eye protection, and a dust mask. Ensure adequate ventilation during application, and review first aid measures.

Personal Protective Equipment (PPE)

Prior to commencing SPECTRALOCK 1 application, prioritizing personal safety is paramount. Essential Personal Protective Equipment (PPE) includes, but isn’t limited to, the consistent use of chemical-resistant gloves to prevent skin contact and potential irritation.

Furthermore, safety glasses or goggles are crucial for safeguarding your eyes from splashes or dust particles. A properly fitted dust mask or respirator is highly recommended, especially during mixing or application in enclosed spaces, to avoid inhaling grout dust.

Appropriate clothing, such as long sleeves and pants, should be worn to minimize skin exposure. Always inspect PPE for damage before each use, and replace any compromised items immediately. Following these guidelines will significantly reduce the risk of discomfort or injury during the installation process.

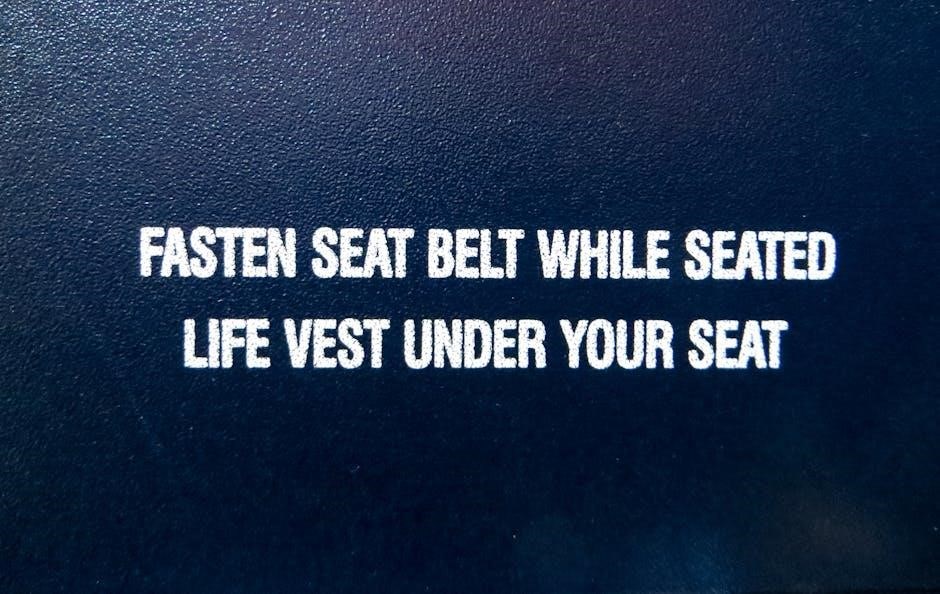

Ventilation Requirements

Adequate ventilation is critical when working with SPECTRALOCK 1, even though it’s a low-VOC product. Ensure sufficient fresh air circulation in the application area to minimize the build-up of any potential fumes or dust. Opening windows and doors can provide natural ventilation, but may not always be sufficient.

For enclosed or poorly ventilated spaces, the use of a mechanical ventilation system is strongly recommended. This could include exhaust fans or a portable air purifier with a HEPA filter.

Proper ventilation not only protects the installer but also contributes to a more comfortable working environment. Always assess the space and implement ventilation measures accordingly, prioritizing a safe and healthy atmosphere throughout the installation process.

First Aid Measures

In case of eye contact with SPECTRALOCK 1, immediately flush with copious amounts of clean, lukewarm water for at least 15 minutes, occasionally lifting the upper and lower eyelids. Seek medical attention if irritation persists.

For skin contact, wash the affected area thoroughly with soap and water. If irritation develops, consult a physician. Remove contaminated clothing and launder before reuse.

If SPECTRALOCK 1 is ingested, do NOT induce vomiting. Rinse the mouth with water and seek immediate medical attention. Inhalation of dust or fumes may cause respiratory irritation; move to fresh air and consult a doctor if symptoms develop.

Technical Data and Specifications

SPECTRALOCK 1’s physical and chemical properties are detailed in Data Sheet 36589.5, providing comprehensive specifications for professional application and performance expectations.

Physical Properties of Spectralock 1

SPECTRALOCK 1 exhibits exceptional physical characteristics crucial for durable tile and grout installations. This pre-mixed epoxy grout demonstrates high compressive strength, ensuring resistance to cracking and deformation under load. Its density contributes to its non-sagging properties, particularly beneficial for vertical surfaces and large format tile applications.

The grout’s low water absorption minimizes staining and facilitates easy cleaning. SPECTRALOCK 1 also boasts excellent flexibility, accommodating minor substrate movements without compromising the integrity of the grout lines. Detailed physical property data, including weight per cubic foot and specific gravity, are comprehensively documented within LATICRETE’s Data Sheet 36589.5, providing installers with precise technical information for optimal performance.

Chemical Resistance

SPECTRALOCK 1 demonstrates superior resistance to a wide array of chemicals, making it ideal for demanding environments. This epoxy grout withstands exposure to acids, alkalis, solvents, and household cleaning agents without significant degradation or discoloration. Its chemical inertness ensures long-term performance in kitchens, bathrooms, laboratories, and commercial facilities.

This resistance extends to common staining agents like oils, grease, and wine, simplifying maintenance and preserving aesthetic appeal. Detailed chemical resistance testing results, outlining performance against specific substances, are thoroughly documented in LATICRETE’s Data Sheet 36589.5. This resource provides installers and specifiers with critical information for selecting SPECTRALOCK 1 in chemically aggressive applications.

Data Sheet 36589.5 Reference

LATICRETE Data Sheet 36589.5 serves as the definitive resource for comprehensive SPECTRALOCK 1 installation guidance. This document details crucial aspects, including surface preparation, mixing (though premixed, handling is covered), application techniques, and troubleshooting common issues. It outlines substrate requirements, joint width recommendations, and considerations for vertical surfaces and large format tile installations.

The data sheet also provides vital information on physical properties, chemical resistance, and safety precautions. It’s essential reading for installers to ensure proper application and maximize product performance. Accessing and thoroughly reviewing 36589.5 prior to commencing work guarantees adherence to best practices and validates warranty coverage.

Spectralock 1 Application Resources

Access LATICRETE representative support for expert guidance. Explore online tutorials and videos, and review Product Overview model 3191-0001-2 for detailed application assistance.

LATICRETE Representative Support

For personalized assistance with SPECTRALOCK 1 installations, connect with a dedicated LATICRETE representative. These professionals possess in-depth knowledge of the product’s characteristics and application techniques, offering tailored solutions to address specific project challenges. They can clarify details found within Data Sheet 36589.5, ensuring a smooth and successful grouting process.

Representatives like Brett Tanos, Phil Pearson, and Daren Fakas provide valuable insights, demonstrated through their reviews of SPECTRALOCK 1. They can assist with troubleshooting, offer guidance on optimal grout selection for various tile types, and help interpret the instructions outlined in model 3191-0001-2. Contacting a LATICRETE representative guarantees access to expert support throughout your project lifecycle.

Online Tutorials and Videos

Enhance your understanding of SPECTRALOCK 1 application through readily available online resources. LATICRETE provides a wealth of instructional videos and tutorials designed to guide users through each step of the installation process, complementing the detailed instructions in Data Sheet 36589.5.

These visual aids demonstrate proper mixing techniques, grout application methods, and effective cleaning procedures. Content features insights from LATICRETE product managers like Ryan Blair, explaining the benefits and optimal uses of SPECTRALOCK 1. Access these resources to visualize best practices and confidently tackle your tiling project, referencing model 3191-0001-2 for specific guidance.

Product Overview and Model 3191-0001-2

SPECTRALOCK 1 (model 3191-0001-2) represents a significant advancement in pre-mixed grout technology, offering exceptional performance and ease of use. This innovative product eliminates the need for on-site mixing, ensuring consistent quality and reducing application time. LATICRETE representatives, including Brett Tanos, Phil Pearson, and Daren Fakas, highlight its benefits.

Detailed instructions for this model are available, covering safety precautions, setup procedures, and application techniques. Referencing Data Sheet 36589.5, “How To Install SPECTRALOCK 1 Pre-Mixed Grout,” is crucial for optimal results. Understanding the product’s features and adhering to the guidelines ensures a durable and aesthetically pleasing tile installation;